Robis

Home Lab

Improve the world

Welcome to Meteor-M!

Purpose

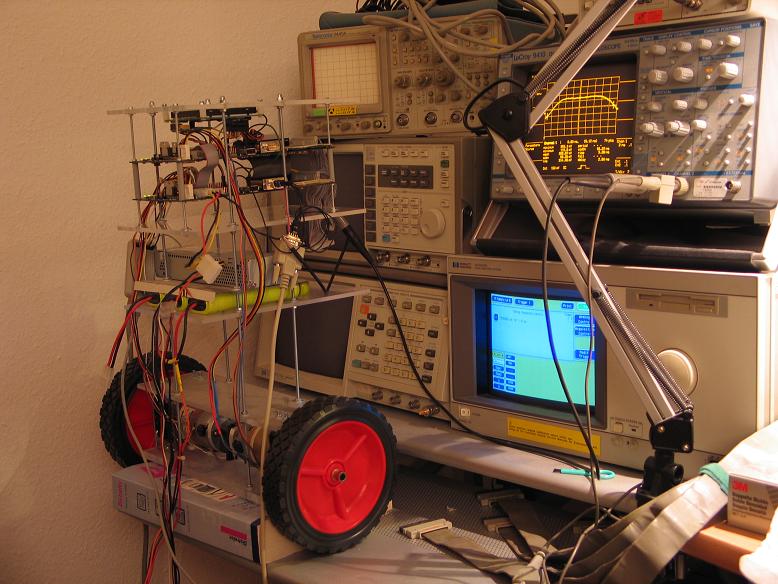

RIM-II and RIM-I robots are designed to facilitate the custom processor IP benchmarking in the “real world” conditions.

In a sense RIM is the two wheeled autonomous regression test bench for the dedicated application specific IP core debugging and benchmarking.

Robis_M2_2013

Robis_M2_2013

RIM-II also employs the inverted pendulum arrangement managed by the ROBIS FPGA re-configurable embedded control system, which is designed to fulfill the following tasks:

Sensor data acquisition;

Sensor fusion;

Dynamic stability and trajectory control (position, speed and acceleration);

Dynamic adaptability to the various mechanical objects being transported;

Machine vision including the stereo vision range finding, Simultaneous Localization and Mapping (SLAM);

Real-time embedded benchmarking;

Telemetry;

High level mission task

The benchmarking task logs the stimuli and the real-time benchmark data for the further analysis on the system level simulator. The offline analysis therefore, can provide the details about the computational efficiency of the CPU core, peripheral IP modules, etc.

User via the RF link and HOST software can change on the fly the test scenarios pushing the robot to the limits of dynamic envelope.

Mechanical Design

The second generation of RIM robot adds the mechanical precision and extends its dynamic envelope. The backlash problem is successfully solved by moving from the geared drive train to the timing belt driven wheel hubs. The pancake motors provide higher torque. Overall drive train has 2 times less momentum of inertia comparing to the first generation robot.

The chassis has elevated center of gravity by having all the heavy components(motors, battery, electronics) placed above the axis of rotation.

The robot chassis comprises the following components:

Drivetrain compartment housing 2 pancake 24V DC motors with optical encoders

Timing belt transmission with elastic tensioners

Main axis with the wheel hubs and pneumatic wheels

ROBIS control system

5A/h LiPo battery

VGA LCD display

Stereovision assembly holding two global shutter cameras and BINOCULUS adapter.

Electrical Design

The robot electronics is based on the ROBIS platform in the following configuration:

Two ROBIS rev2 controllers

Display shield board

Stereovision BINOCULUS adapter

Power distribution and conversion module

Performance

The robot stands 0.5m and weights about 13 kg.

RIM-II can transport an object of up to 3kg positioned at any point of its payload adapter (robot top acrylic sheet) with a speed of up to 5km/h uphill or downhill with the maximum ramp inclination of 15%.

Robis_M2_2013_1

Robis_M2_2013_1

The battery capacity is sufficient to run at the full load for 1 hour. Object properties are extracted in form and color bins and superimposed on the range finding information from the stereo vision system.

Next Generation

Next generation robot chassis will be equipped with the 5 DOF manipulator to handle (move, load/unload) the small objects